Shandong Leader Machinery Co.,ltd. have engaged in Oil Refinery Equipment and Microwave Equipment since1997 in China,with 20 years` experience and 80 engineers,, scientific research, manufacturing, installation, commissioning.We can provide customers with design and services of 1-2000 tons oil equipment.factory occupied area is over 100,000 square meters,more than 3200 customers all around the world, we greatly hope to have the opportunity to serve you.

Shandong Leader Machinery Co.,ltd. has finished hundreds of successful projects over the years: peanut oil, soybean oil, rapeseed oil, cottonseed oil, sunflower oil, sesame oil, animal oil,grape seed oil, acer truncatum oil, peony seed oil, walnut oil, hemp seed oil, pine oil, tea seed oil, papaya oil, milk thistle seed, and other special type oil.We have independent import and export department. Our equipment has been successfully exported to more than 100 countries: Russia, Australia, India, Afghanistan, Cameroon,and so on.

Product Description

Company Profiles:

LD &Oil Machinery Co.,Ltd is a large-sized joint-equity enterprise which specialize in producing edible oil mechanical equipment and it is also a group enterprise integrating scientific research, manufacturing, sales as one. Research Institute of Machine Design Company and LD, LD University of Technology (formerly the LD College) school-enterprise cooperation in the oil equipment to carry out long-term, protein extraction, phospholipid extraction, etc. R & D and application of new technologies.

Main business:

10-500T/H oil material first cleaning,drying and storage section turn-key project.

100-3000 T/D oil pretreatment, shelling and pre-press workshop turnkey project (soybean hot peeling, bean skin crushing; the soybean extrusion, high oil contained pre-press cake extrusion, and high oil contained embryos puffed; of direct puffed). Rice bran production line turn-key project.

Leaching workshop turnkey project (Towline extractor, Rotocel extractor, loop type extractor, LD separated machine, the full negative pressure evaporation, paraffin wax recovery, leaching workshop degum, phospholipid concentrate).

30-1000T/D oil continuous grade two or one physical (chemical) refining production line.

20-600T/D sunflower oil, rice bran oil, corn germ oil dewaxing turn-key project.

10-200T/D Fatty acid esterification production cooking oil production line, and so on.

sunflower seed peeling machine

Main Features

1) Engineer guide you installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) Regard quality as the company life ,regard user as the god,mutual benefit and win-win situation with integrity,tenet.

4) Running in a high automatization and intellectualization,no pollution.

5) Long life to use, and 24 hours online service for you.

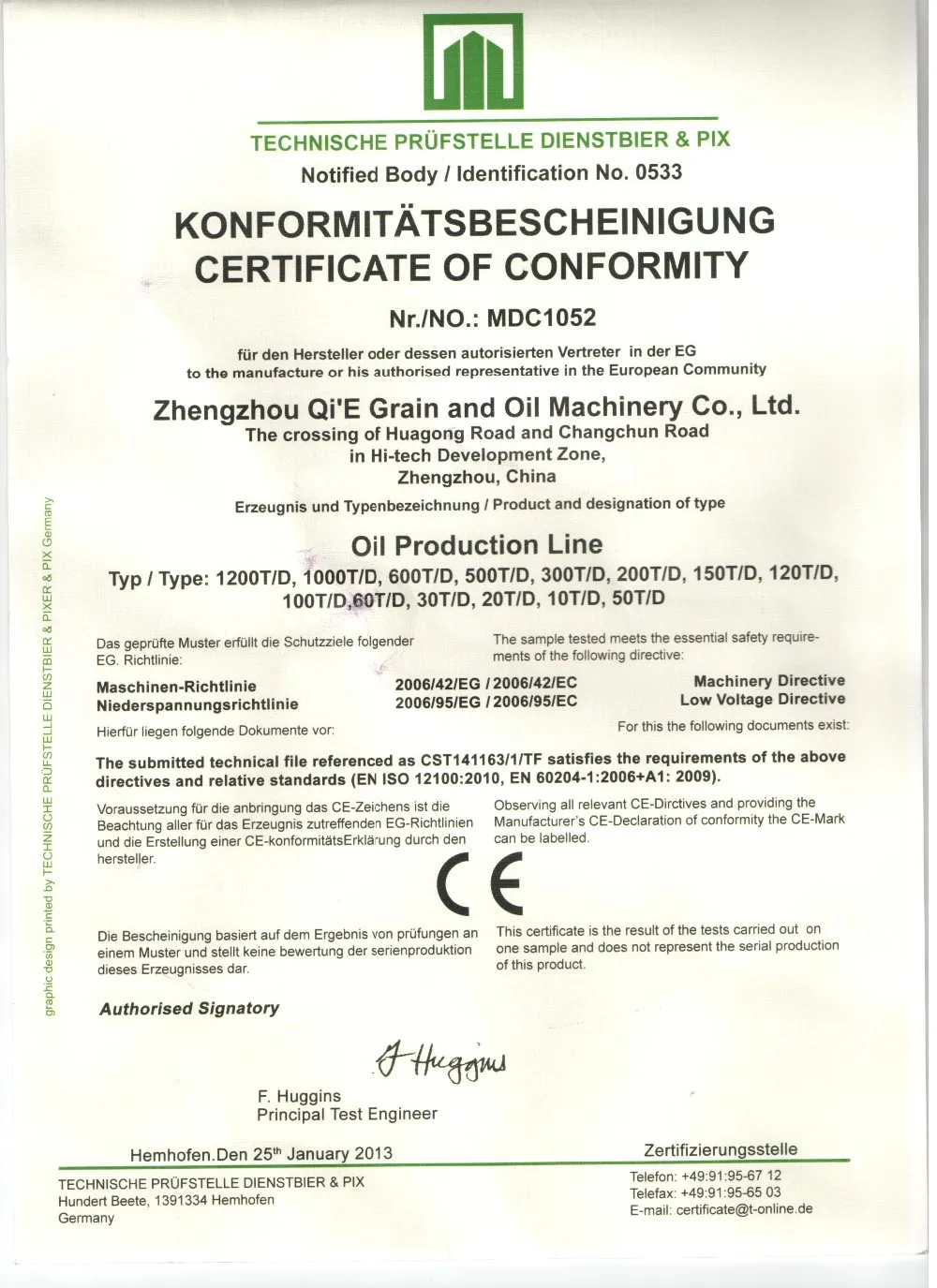

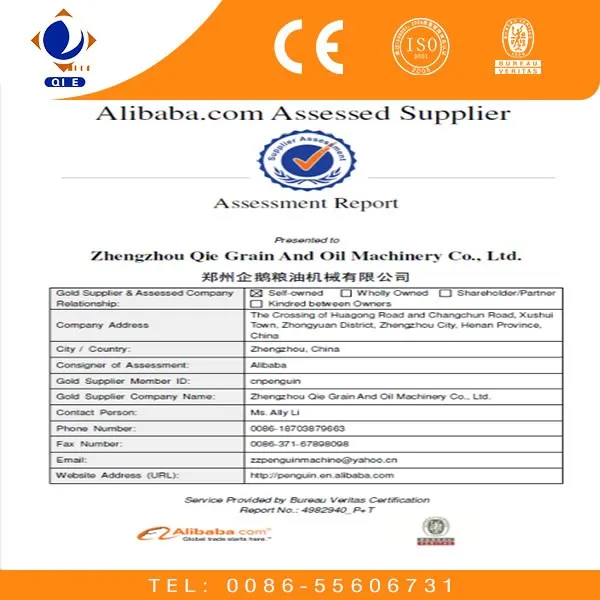

Certifications

Certifications

Detailed Images

Detailed Images

Machine Parts

Name: Pretreatment Plant

Brand: LD

Original: China

Rice bran extrusion flow chart:

Rice branâMagnetic separationâCleaning âExtrusion Puffing âCounter-current dryingâTo leaching plant

Main Features

Name: Cleaning process

Brand: LD

Original: China

Adopt the magnetic separation removing iron miscellaneous and vibration sieve removing broken clear, rice Xi, etc.

Machine Parts

Name: Extrusion process:

Brand: LD

Original: China

Adopting the bulking machine can both improve the yield of rice bran oil and reduce the consumption. The extrusion puffing, on the one hand, can make solution lipase in the rice bran passivated under high temperature and high pressure condition,then prevent the rice bran oil rancidity; On the other hand, the extrusion puffing can make rice bran be porous mateial , and increases the materials bulk density, then improve the permeability and leaching rate which solvent reacts to the material.

Main Features

Name: Drying process

Brand: LD

Original: China

The puffed rice bran contains about 12% water, and the moisture for leaching process is 7-9%, therefore, there must be effective drying means to achieve the leaching moisture.Adopting counter-current dryer can make water and temperature meet with follow-up process requirements, and improve the oil yield, as well as oil quality.

Our Service

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Packing & Delivery

| Packaging | |

| Size | 123 (L) * 456 (W) * 789 (D) |

| Weight | 1.2 T |

| Packaging Details |

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

| Packaging | |

| Size | 123 (L) * 456 (W) * 789 (D) |

| Weight | 1.2 T |

| Packaging Details |

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

Sunflower meal extraction oil machine

91.8% Response Rate

sunflower seed hulling machine

91.8% Response Rate

sunflower seed roasting machine

91.8% Response Rate

In order to obtain high effective cleaning, ensure good work condition and production stability, high efficient

vibration screen was used in the process to separate big and small impurity.

Suction type gravity stoner removing machine was applied to remove the shouLDr stone and earth, and

magnetic separation equipment without power and exhaust system were used to remove iron.

Dust removing wind net is installed. soybean oil machine

AAA1

2017 the latest technology Sunflower seed peeling machine is a crushing machine equipment that use the double tooth roller for granular material on two consecutive crushing processing,in order to meet the requirement of process.This 2017 the latest technology Sunflower seed peeling machine - Crusher Machine is suitable for the crushing processing of soybeans,peanuts and soybean meals and etc.

AAA2

If you have any demand about microwave drying equipment and edible oil refining equipment, pls feel free contact us any time.

LD Miss Candy

Skype: leaderfoodmachine9

Mobile: +86 18363700691 (Also WhatsApp & Wechat)

Email: [email protected]